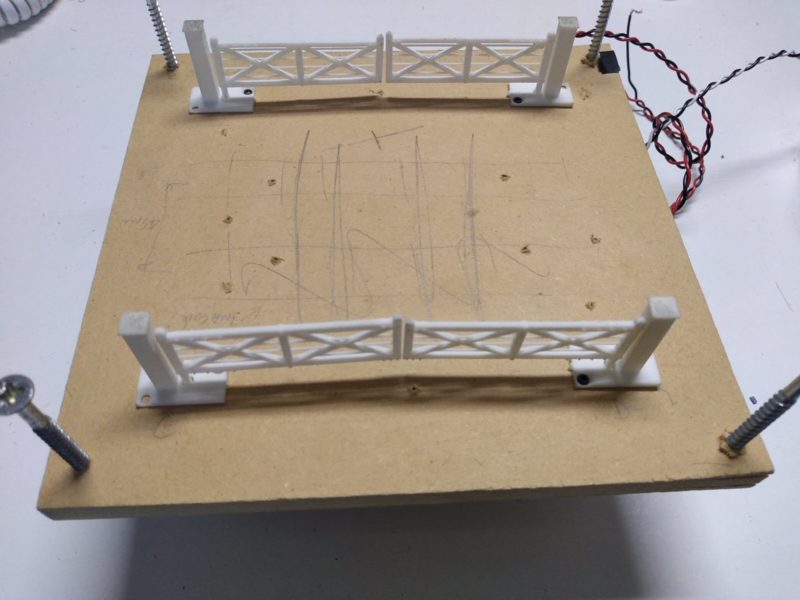

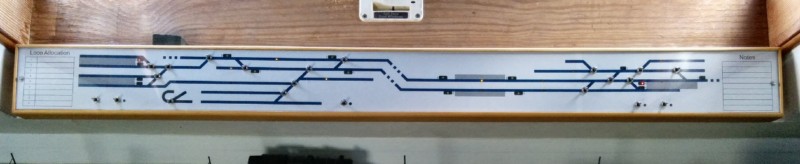

Our Model Railway Club is starting a new 009 (Narrow Gauge) layout and we needed a couple of control panels to control it. Being a small layout, it is much simpler than previous designs and small enough to 3D print.

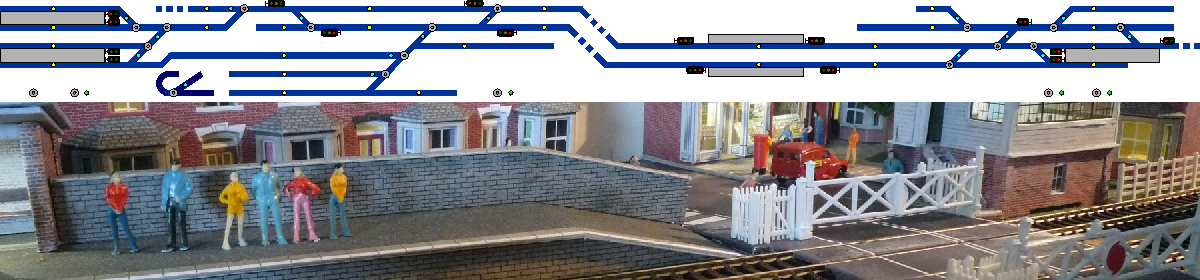

The first stage was to design the front panel layout:

As this is designed to be used from either the front and the back of the layout, there is no text on this as it will be used “upside down” at the front. This was printed, then holes punched out for the LEDs, then laminated, then holes punched out for the switches.

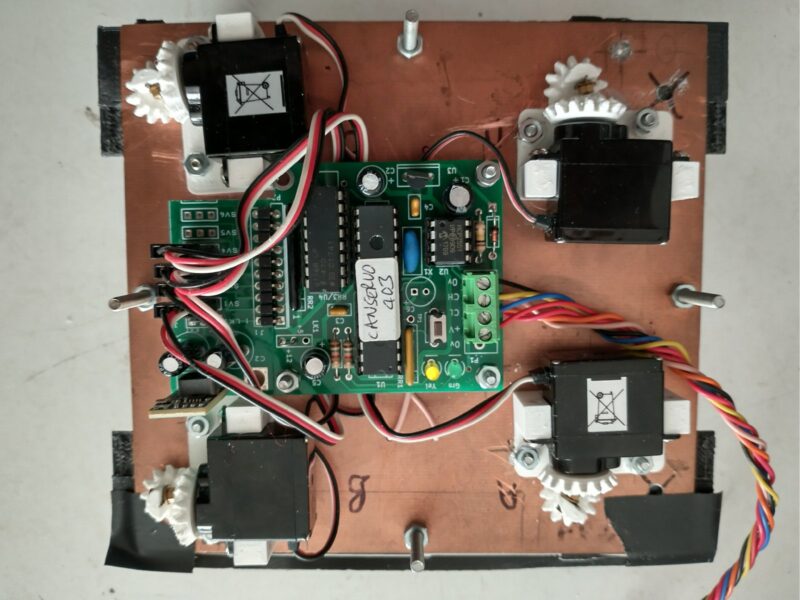

The next stage was to design the case. The vents in the bottom part were added in case the electronics got a bit warm:

The switches and LEDs are fitted to the top section and marked:

Then the ribbon cable that connects to the control board is fixed using the cable clamp printed earlier:

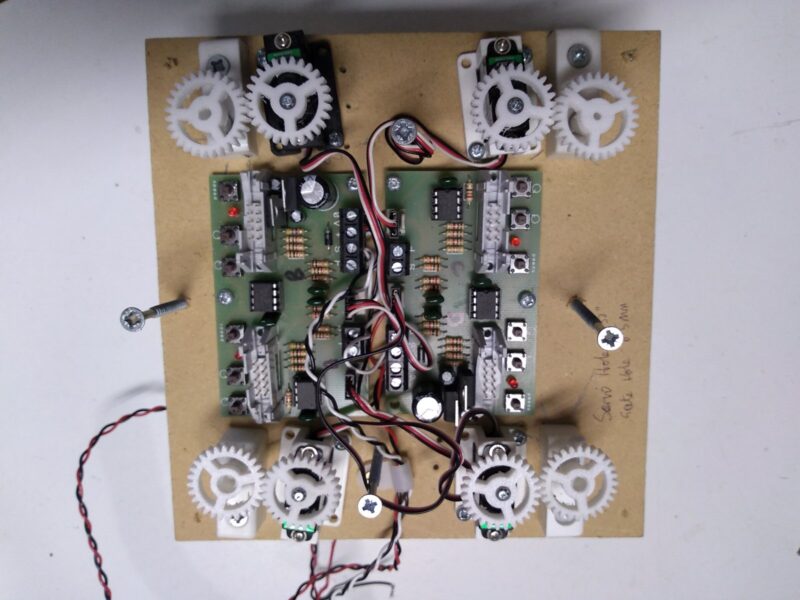

The LEDs are wired first, then the switches:

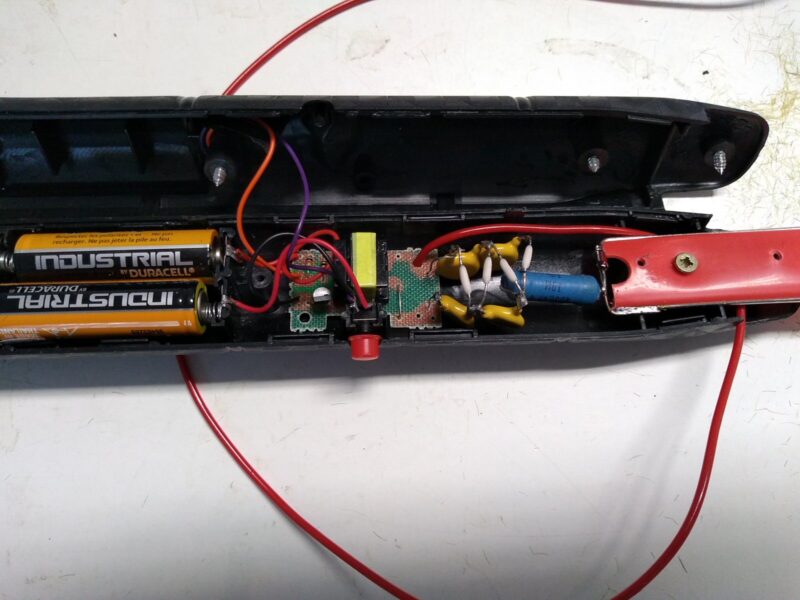

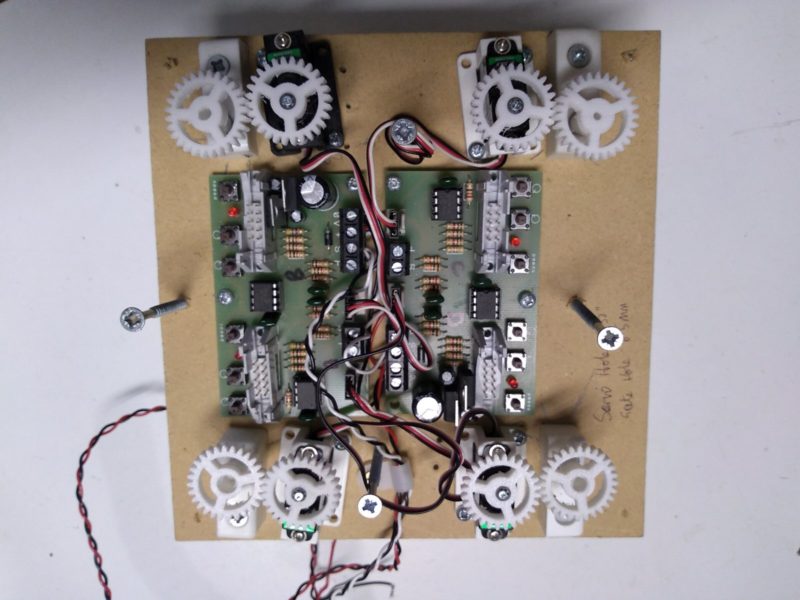

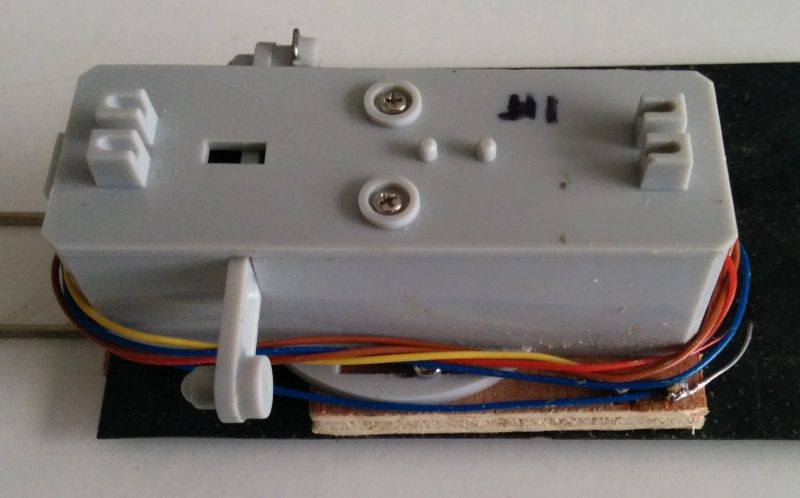

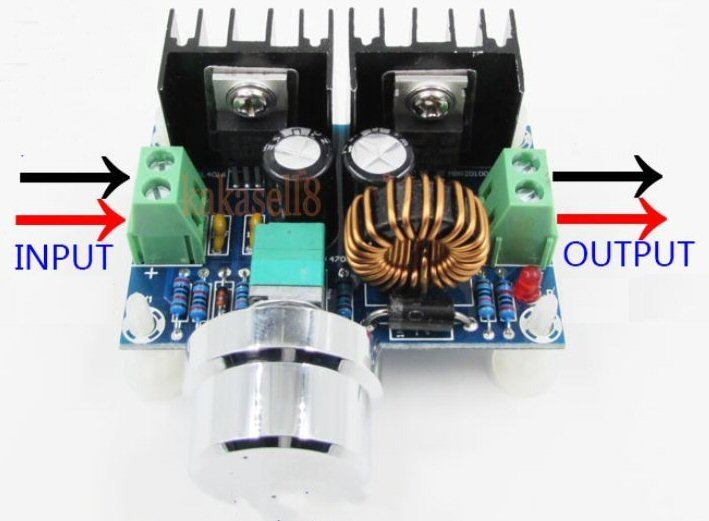

The control board is screwed to the bottom of the case and a power/signal cable added to connect it to the layout:

Then the two parts are connected and tested:

The two parts of the case are then screwed together:

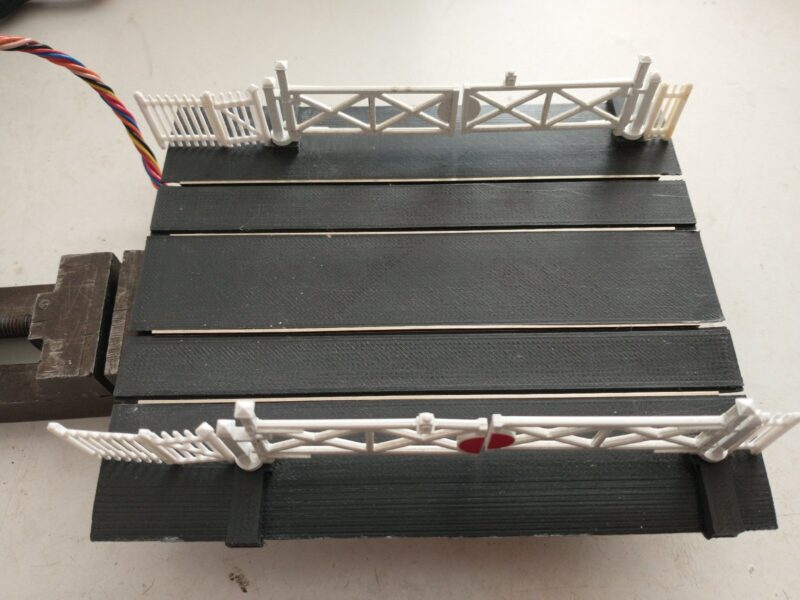

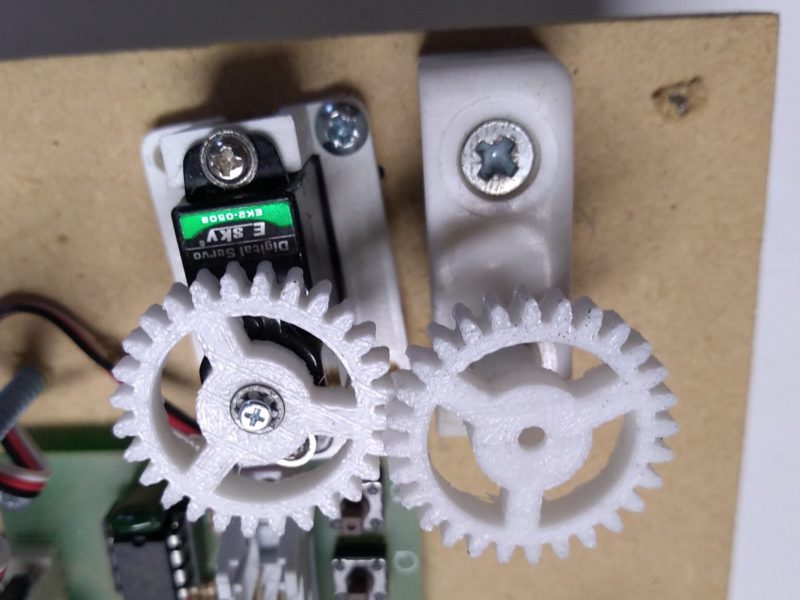

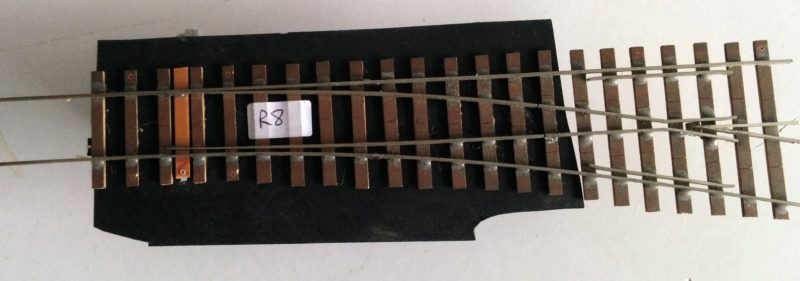

The switches are spring loaded “centre-off” switches as the LEDs can be changed from the other control panel or other sources. Once the layout is built, servos will move the points as indicated by the LEDs.